Reliability

Who Has Time for Downtime?

We designed the Crossfire to be easy and simple to maintain while providing years of trouble-free use. Some of the key built-to-last features found in the Crossfire line includes:

-

Polyethylene hopper provides years of service and will not rust or corrode.

-

Heavy-duty 1/2-horsepower auger motor grinds through tough chunks providing an even material flow to the auger.

-

Low friction poly auger bearing requires no lubrication or maintenance.

-

Auger assembly can quickly be removed for inspection or maintenance.

- The spinner assembly can be removed making it easy to offload material at the end of a long shift.

Ease of Use

Thoughtful Features, Premium Performance

Being out on the road in the snow and ice makes for a long night. That's why we made many of the ease-of-use features that are options on competitive spreaders standard on the Crossfire. These include:

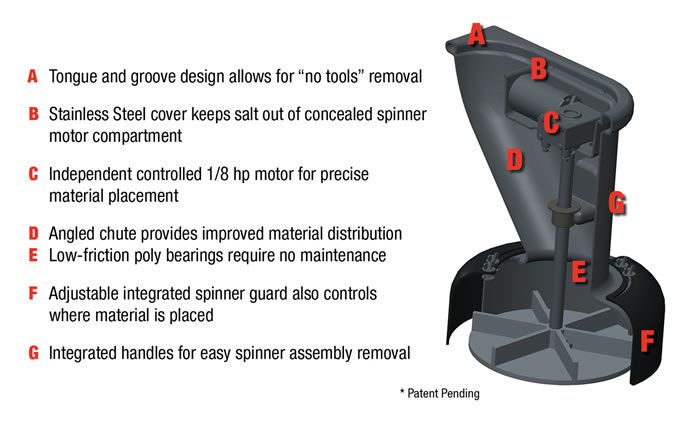

No Tools, Easy Maintenance Spinner Assembly

The patent-pending spinner assembly comes standard with an 18.5” length or you can upgrade to a 26.5” length. See why the Crossfire’s spinner assembly is so easy to use and maintain:

Off-Season Storage

The Crossfire stores upright during the off-season, saving valuable storage space.

Work Light

The integrated work light illuminates the spread area and helps during maintenance.

Deluxe Controller

The deluxe controller allows the user to adjust the flow of material to their preference. It also controls the flow of pre-wet liquid material for pre-wetting granular ice control material. The deluxe controller can detect a jam in the material delivery system and will automatically reverse feed the material in order to clear a jam without user intervention.